Sour Water Stripping

Sour water is condensed waste water produced during many downstream refining processes containing hydrogen sulfide, ammonia and other contaminating compounds. It is often acidic in nature and can cause corrosion problems within the refinery’s pipework so it must be treated before it can be reused or disposed to the waste water treatment plant.

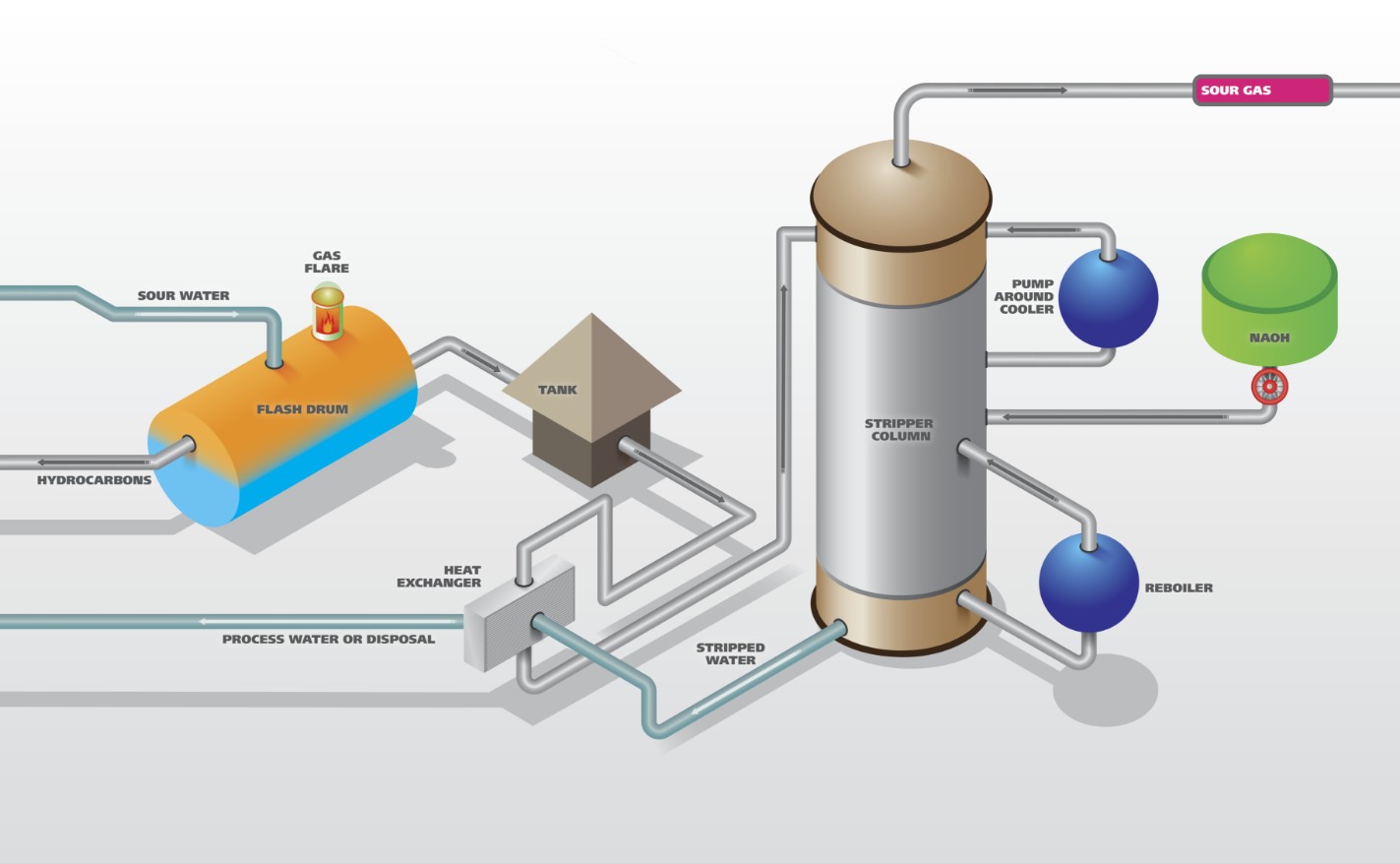

Sour water is treated in the Sour Water Stripper (SWS) which uses a steam stripping process to remove sulfides and ammonia as gases. At optimum pH the sour water mixes with steam and the ammonia and hydrogen sulphide gas vent to the top of the stripper column to the Sulfur Recovery Unit (SRU). The stripped water is either used to produce steam in the reboiler or pumped within control limits to the waste water treatment plant for further processing.

Online Monitoring of Hydrogen Sulfide and Ammonia

Online analysis of ammonia and sulfides increases the efficiency of the SWS which leads to significant steam reduction and increased energy savings. Effectively stripping and monitoring H2S and NH3 is an essential operation in the overall pollution reduction program of refineries. The Process Analyzer 2045TI can analyze H2S and NH3 simultaneously with automatic cleaning and calibration using absolute wet chemical techniques. Fast and accurate results are continuously transmitted for process control.

Other contaminants that increase the sour water corrosiveness like phenol and cyanide can also be analyzed with Metrohm Process Analyzers.

Determination of Anions, Sulfide, and Ammonium by Ion Chromatography

Determination of sulfide and other sulfur species is critical for strict SWS process monitoring. While titration is a suitable technique for the sulfide content, the other corrosive sulfur species can be determined by ion chromatography. The degradation products of sulfide, such as sulfite, sulfate, thiosulfate and thiocyanate can be monitored by suppressed ion chromatography. Sulfide content in sour water can be monitored with UV detection while ammonia content can be monitored by cation exchange chromatography. Sample preparation steps such as ultrafiltration and dilution can be automated.